| Sign In | Join Free | My qualitytoyschina.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My qualitytoyschina.com |

|

Brand Name : Supreme

Model Number : FM-350

Place of Origin : China

Certification : CE

MOQ : 1

Price : negotiation

Packaging Details : fumigation wooden box

Delivery Time : 30-60 working days

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 20sets/month

Max laminating speed : 65m/min

Machine size : 1655*1030*1235mm

Warranty : 1 Year

Total power : 16.5kw

Model : FM-350

Machine weight : 450kg

Max paper diameter : 600mm

Suit for paper thickness : 105-500gsm

Video : For Video Sent Please Wechat/wa Me:+8618072118971

Language : Can Customized Into Client Regular Language For Easy Operations

Product name : SUIT FOR PAPER THICKNESS 105-500GSM ROLL TO ROLL PRE COATING FILM LAMINATING MACHINE COMPACT STRUCTURE SAVE LOT MATERIAL

Note : Because Of Upgraded And Development, Machine Image Just For Reference, For The Newest Machinery, Please Enquiry Our Company. The Finally Interpretation Is Owned By Our Company

http://www.youtube.com/@labelturretrewindingmachinery

This machine has a compact structure, which saves a lot of land space for enterprises and it gives them the ability to select pre-coating film which is lower in cost than ordinary cold film. Moreover, it has a unique magnetic powder tension control for unwinding and rewinding to ensure quality.

It also has an automatic web guide which ensures perfect coating even for uneven products, so they will save a lot material. It is an essential post press tool for large printing companies.

Major printing enterprises need a post press helper to complete the whole printing process. That machine is indispensable for them. It can effectively reduce labor costs, improve printing enterprises' production efficiency and accuracy.

SUIT FOR PAPER THICKNESS 105-500GSM ROLL TO ROLL PRE COATING FILM LAMINATING MACHINE COMPACT STRUCTURE SAVE LOT MATERIAL

Supreme's FM-350 SUIT FOR PAPER THICKNESS 105-500GSM ROLL TO ROLL PRE COATING FILM LAMINATING MACHINE COMPACT STRUCTURE SAVE LOT MATERIAL is a Water Based Thermal Film Laminating Machine that uses the skills of Pre-coating Film Laminating Machine. It is a Fully Automatic Hot Knife Pre-coating Thermal Film Laminating Machine, with a max laminating speed of 65m/min, total power of 16.5kw, machine weight of 450kg, and machine size of 1655*1030*1235mm. It is suitable for paper thickness of 105-500gsm. All of our machines are CE certified, and our minimum order quantity is 1. The price is negotiable, and the packaging will be fumigation wooden box. The delivery time is 30-60 working days, and the payment terms are TT;LC. We have a supply capacity of 20sets/month.

SUIT FOR PAPER THICKNESS 105-500GSM ROLL TO ROLL PRE COATING FILM LAMINATING MACHINE COMPACT STRUCTURE SAVE LOT MATERIAL provides technical support and services to help customers get the most out of their products. Our experienced technicians are available to diagnose and repair any issues that may arise. We also provide customer support in the form of online tutorials, FAQs, and troubleshooting guides. Our team is committed to providing the best possible service and support for our customers.

Our SUIT FOR PAPER THICKNESS 105-500GSM ROLL TO ROLL PRE COATING FILM LAMINATING MACHINE COMPACT STRUCTURE SAVE LOT MATERIAL is shipped to customers in a wooden crate which is designed to protect the machinery from any potential damage..

To ensure that the SUIT FOR PAPER THICKNESS 105-500GSM ROLL TO ROLL PRE COATING FILM LAMINATING MACHINE COMPACT STRUCTURE SAVE LOT MATERIAL arrives in perfect condition, we also pack the crate with a cushioning material to absorb the shock of transit. The crate is then placed on a pallet and shrink-wrapped for extra protection.

We offer shipping through various third-party providers to ensure that the product is delivered on time and in perfect condition. We also provide tracking information for customers to monitor the progress of their order.

Specifications:

| model | FM-350 |

| Max paper diameter | 600mm |

| Suit for paper thickness | 105-500gsm |

| Max laminating speed | 65m/min |

| Total power | 16.5kw |

| Machine weight | 450kg |

| Machine size | 1655*1030*1235mm |

1:The Orange-red baffle in the image is used to limit the position of the web paper, so as to avoid beyond the scope of correction

during processing.

2:The yellow part in the image shows the manual oil pump, and above the oil pump is an oil pressure gauge for easy operation and monitoring of oil pressure at any time. The black valve body is locked to prevent oil pump pressure drop. The blue valve body at the bottom serves as a pressure regulating function, allowing for specified pressure and making it easier to achieve the required pressure by adjusting it

3:Image 1 shows the overall deviation correction device. image 2 shows a U-shaped opposing sensor, which has high accuracy in correcting deviation and can accurately correct deviation regardless of the transparency of the material

4:When one roll is finished and the next roll is replaced. Having this device can avoid frequent machine adjustments, paper threading, and positioning. Reduce machine stopping time

5:216mm large diameter heating roller. The surface of the roller is polished with a mirror, providing a better texture, durability, and wear resistance. Stable heating.

6:Commonly used for pre coating films with poor quality, wrinkles, unevenness, and uneven left and right sides. The left and right eccentric blocks can be adjusted appropriately. Maintain consistent tension between the left and right sides of the film to avoid wrinkling before entering the heating roller and affecting the quality of the film coating

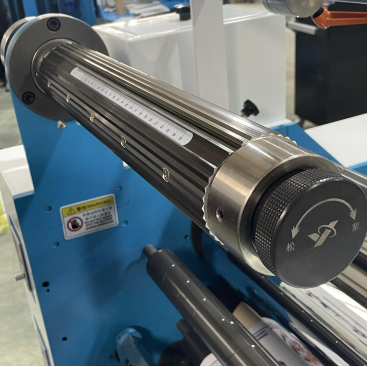

7:This machine adopts three tile type expansion shafts and abandons the fixed mode of air expansion shaft, completely freeing the machine from the constraints of the air compressor. Tile type expansion shaft is more convenient and fast

8:Effectively control the tension of the film release shaft to prevent wrinkling caused by relaxation of the pre coated film, which affects the processing effect.

9:paper drawing:

|

|

SUIT FOR PAPER THICKNESS 105-500GSM ROLL TO ROLL PRE COATING FILM LAMINATING MACHINE COMPACT STRUCTURE SAVE LOT MATERIAL Images |